Abstract

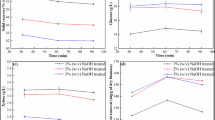

Phragmites karka is one of the fast growing halophytes known to accumulate high biomass in a short span of time. In this study, we evaluated the potential of P. karka biomass from the Chilika Lagoon of India for the production of glucose which can possibly be converted into ethanol. Compositional analysis of biomass of P. karka was carried out and it was found that the biomass contained 33.12% cellulose, 28.17% hemicellulose and 24.81% lignin. For saccharification, the biomass were pretreated with two different pretreatments such as, cellulose solvent -and organic-solvent based lignocellulosic fractionation (COSLIF) and alkali (NaOH). Both of the pretreated biomass were digested with various dosages of cellulase and β-glucosidase enzymes. The enzymatic hydrolysis revealed that COSLIF using 85% phosphoric acid at a solid loading of 1 g biomass to 8 ml acid for 45 min at 50 °C exhibited the best result in terms of glucose release. Cellulase enzyme mixture containing 1 FPU cellulase and 10 IU β-glucosidase was found efficient in releasing 86.16% of glucose from the COSLIF pretreated biomass, whereas with the use of higher dosages of enzyme mixture (60 FPU cellulase and 60 IU β-glucosidase) alkali pretreated biomass could release only 72.65% glucose. The findings in this study addressed the potential use of P. karka as a source of biomass for the second generation ethanol production.

Graphical abstract

Similar content being viewed by others

Abbreviations

- COSLIF:

-

Cellulose solvent- and organic solvent lignocellulose fractionation

- FPU:

-

Filter paper unit

- IU:

-

International units

- AIL:

-

Acid-insoluble lignin

- ASL:

-

Acid-soluble lignin

- FT-IR:

-

Fourier transform infrared spectroscopy

References

Agrawal R, Singh NR, Ribeiro FH, Delgass WN (2007) Sustainable fuel for the transportation sector. Proc Natl Acad Sci 104:4828

Liao JC, Mi L, Pontrelli S, Luo S (2016) Fuelling the future: microbial engineering for the production of sustainable biofuels. Nat Rev Microbiol 14:288

Robertson GP, Hamilton SK, Barham BL, Dale BE, Izaurralde RC, Jackson RD et al (2017) Cellulosic biofuel contributions to a sustainable energy future: choices and outcomes. Science 356:eaal2324

Li W, Ciais P, Makowski D, Peng S (2018) A global yield dataset for major lignocellulosic bioenergy crops based on field measurements. Scientific data 5:180169

Zhang F, Rodriguez S, Keasling JD (2011) Metabolic engineering of microbial pathways for advanced biofuels production. Curr Opin Biotechnol 22:775

Zhang X, Qu T, Mosier NS, Han L, Xiao W (2018) Cellulose modification by recyclable swelling solvents. Biotechnol Biofuels 11:1

Zhang Y-HP, Zhu Z, Rollin J, Sathitsuksanoh N (2010) Advances in cellulose solvent-and organic solvent-based lignocellulose fractionation (COSLIF). Cellulose solvents: for analysis, shaping and chemical modification. ACS Publications

Nargotra P, Sharma V, Gupta M, Kour S, Bajaj BK (2018) Application of ionic liquid and alkali pretreatment for enhancing saccharification of sunflower stalk biomass for potential biofuel-ethanol production. Biores Technol 267:560

Somerville C, Youngs H, Taylor C, Davis SC, Long SP (2010) Feedstocks for lignocellulosic biofuels science 329:790

Nayak SS, Pradhan S, Sahoo D, Parida A (2020) De novo transcriptome assembly and analysis of Phragmites karka, an invasive halophyte, to study the mechanism of salinity stress tolerance. Sci Rep 10:1

Shoukat E, Abideen Z, Ahmed MZ, Gulzar S, Nielsen BL (2019) Changes in growth and photosynthesis linked with intensity and duration of salinity in Phragmites karka. Environ Exp Bot 162:504

Adney B, Baker J (1996) Measurement of cellulase activities. Laboratory analytical procedure 6:1996

Wood TM, Bhat KM (1988) Methods for measuring cellulase activities. Methods Enzymol 160:87

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D et al (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory analytical procedure 1617:1

Sluiter A, Ruiz R, Scarlata C, Sluiter J, Templeton D (2005) Determination of extractives in biomass. Lab Anal Procedure (LAP) 1617:1

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D. (2005) Determination of ash in biomass (NREL/TP-510–42622). National Renewable Energy Laboratory, Golden

Sathitsuksanoh N, Zhu Z, Templeton N, Rollin JA, Harvey SP, Zhang YP (2009) Saccharification of a potential bioenergy crop, Phragmites australis (common reed), by lignocellulose fractionation followed by enzymatic hydrolysis at decreased cellulase loadings. Ind Eng Chem Res 48:6441

Zhang YHP, Ding SY, Mielenz JR, Cui JB, Elander RT, Laser M et al (2007) Fractionating recalcitrant lignocellulose at modest reaction conditions. Biotechnol Bioeng 97:214

Zhu Z, Sathitsuksanoh N, Vinzant T, Schell DJ, McMillan JD, Zhang YHP (2009) Comparative study of corn stover pretreated by dilute acid and cellulose solvent-based lignocellulose fractionation: enzymatic hydrolysis, supramolecular structure, and substrate accessibility. Biotechnol Bioeng 103:715

Chen Y, Stevens MA, Zhu Y, Holmes J, Xu H (2013) Understanding of alkaline pretreatment parameters for corn stover enzymatic saccharification. Biotechnol Biofuels 6:8

Gao K, Boiano S, Marzocchella A, Rehmann L (2014) Cellulosic butanol production from alkali-pretreated switchgrass (Panicum virgatum) and phragmites (Phragmites australis). Biores Technol 174:176

Wang Z, Keshwani DR, Redding AP, Cheng JJ (2010) Sodium hydroxide pretreatment and enzymatic hydrolysis of coastal Bermuda grass. Biores Technol 101:3583

Mund NK, Dash D, Barik CR, Goud VV, Sahoo L, Mishra P et al (2016) Chemical composition, pretreatments and saccharification of Senna siamea (Lam.) HS Irwin & Barneby: an efficient biomass producing tree legume. Bioresour Technol 207:205

Mund NK, Dash D, Barik CR, Goud VV, Sahoo L, Mishra P et al (2017) Evaluation of efficient glucose release using sodium hydroxide and phosphoric acid as pretreating agents from the biomass of Sesbania grandiflora (L.) Pers.: a fast growing tree legume. Bioresour Technol 236:97

Fike JH, Parrish DJ, Wolf DD, Balasko JA, Green JT Jr, Rasnake M et al (2006) Long-term yield potential of switchgrass-for-biofuel systems. Biomass Bioenerg 30:198

Angelini LG, Ceccarini L, Di Nasso NN, Bonari E (2009) Comparison of Arundo donax L. and Miscanthus x giganteus in a long-term field experiment in Central Italy: analysis of productive characteristics and energy balance. Biomass Bioenergy 33:635

Karp EM, Resch MG, Donohoe BS, Ciesielski PN, O’Brien MH, Nill JE et al (2015) Alkaline pretreatment of switchgrass. ACS Sustainable Chemistry & Engineering 3:1479

He C-R, Kuo Y-Y, Li S-Y (2017) Lignocellulosic butanol production from Napier grass using semi-simultaneous saccharification fermentation. Biores Technol 231:101

Sathitsuksanoh N, Zhu Z, Zhang Y-HP (2012) Cellulose solvent-and organic solvent-based lignocellulose fractionation enabled efficient sugar release from a variety of lignocellulosic feedstocks. Bioresour Technol 117:228

Wells JM, Drielak E, Surendra K, Khanal SK (2020) Hot water pretreatment of lignocellulosic biomass: modeling the effects of temperature, enzyme and biomass loadings on sugar yield. Bioresour Technol 300:122593

Usmani Z, Sharma M, Gupta P, Karpichev Y, Gathergood N, Bhat R et al (2020) Ionic liquid based pretreatment of lignocellulosic biomass for enhanced bioconversion. Bioresour Technol 304:123003

Zhao C, Shao Q, Li B, Ding W (2014) Comparison of hydrogen peroxide and ammonia pretreatment of corn stover: solid recovery, composition changes, and enzymatic hydrolysis. Energy Fuels 28:6392

Xu J, Cheng JJ, Sharma-Shivappa RR, Burns JC (2010) Sodium hydroxide pretreatment of switchgrass for ethanol production. Energy Fuels 24:2113

Moxley G, Zhu Z, Zhang Y-HP (2008) Efficient sugar release by the cellulose solvent-based lignocellulose fractionation technology and enzymatic cellulose hydrolysis. J Agric Food Chem 56:7885

Kataria R, Ruhal R, Babu R, Ghosh S (2013) Saccharification of alkali treated biomass of Kans grass contributes higher sugar in contrast to acid treated biomass. Chem Eng J 230:36

Althuri A, Mohan SV (2019) Single pot bioprocessing for ethanol production from biogenic municipal solid waste. Biores Technol 283:159

Rollin JA, Zhu Z, Sathitsuksanoh N, Zhang YHP (2011) Increasing cellulose accessibility is more important than removing lignin: a comparison of cellulose solvent-based lignocellulose fractionation and soaking in aqueous ammonia. Biotechnol Bioeng 108:22

Sathitsuksanoh N, Zhu Z, Wi S, Percival Zhang YH (2011) Cellulose solvent-based biomass pretreatment breaks highly ordered hydrogen bonds in cellulose fibers of switchgrass. Biotechnol Bioeng 108:521

Haque MA, Barman DN, Kang TH, Kim MK, Kim J, Kim H et al (2013) Effect of dilute alkali pretreatment on structural features and enhanced enzymatic hydrolysis of Miscanthus sinensis at boiling temperature with low residence time. Biosys Eng 114:294

He L, Lv H, Wang C, Zhou W, Pian R, Zhang Q et al (2020) Dynamics of fermentation quality, physiochemical property and enzymatic hydrolysis of high-moisture corn stover ensiled with sulfuric acid or sodium hydroxide. Bioresour Technol 298:122510

Burns D, Ooshima H, Converse A (1989) Surface area of pretreated lignocellulosics as a function of the extent of enzymatic hydrolysis. Appl Biochem Biotechnol 20:79

Lloyd TA, Wyman CE (2005) Combined sugar yields for dilute sulfuric acid pretreatment of corn stover followed by enzymatic hydrolysis of the remaining solids. Biores Technol 96:1967

Ferreira RG, Azzoni AR, Freitas S (2021) On the production cost of lignocellulose-degrading enzymes. Biofuels, Bioprod Biorefin 15:85

Acknowledgements

The authors are grateful to the Forest & Environment Department, Govt. of Odisha for financial support.

Author information

Authors and Affiliations

Contributions

DD: Methodology, Investigation, Visualization. NKM: Conceptualization, Methodology, Investigation, Writing-Original draft. DU: Investigation PM: Feedstock collection, Statistical analysis. SD: Investigation NRN: Conceptualization, Validation, Writing-Review & Editing, Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• An alternative bioenergy feedstock P. karka has been identified to be used for second generation biofuel generation.

• P. karka was found to produced substantial amount of dry biomass, which can reach up to 46 t h−1.

• COSLIF and NaOH pretreatment efficiently released glucose from the biomass.

• Theoretical ethanol yield was estimated to be 51325 kl from the P. karka biomass.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Dash, D., Mund, N.K., Upadhyay, D. et al. Evaluation of alkali and cellulose solvent pretreatments for fermentable sugar production from the biomass of Phragmites karka (Retz.) Trin. ex Steud.: a high biomass producing grass. Biomass Conv. Bioref. 13, 7725–7736 (2023). https://doi.org/10.1007/s13399-021-01730-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01730-4