The trailer is doing a lazy samba behind your SUV as you drive down the highway, swaying side to side far enough to intrude into the neighboring lanes and tug at your truck's rear end. It feels spooky and is, in fact, unsafe. Funny, the thing was as stable as an alpaca on a mountainside when you left this morning. Since then, the only changes you made were to fill the camper's water tank and to load the rear with camping gear and luggage.

Towing a trailer can be a trial. Seemingly minor details—like adding a couple of hundred pounds to the rear—can make profound changes in the rig's stability. But by following a few simple guidelines, you can stay on track, towing with the utmost ease and safety.

The Right Gear

All hitches are not created equal. The weight that your vehicle can tow is specified by the manufacturer and listed in the owner's manual. Find two numbers: the gross trailer weight (GTW) and the maximum tongue weight. With those figures in hand, you can then pick the appropriate hitch; they are split into five classes based on weight:

Class 1: 2000 pounds GTW/200 pounds tongue weight

Class 2: 3500 pounds GTW/350 pounds tongue weight

Class 3: 5000 pounds GTW/500 pounds tongue weight

Class 4: 7500 pounds GTW/750 pounds tongue weight

Class 5: 10,000 pounds GTW/1000 pounds tongue weight

My advice is to install a hitch receiver that's heavy-duty enough to match your vehicle's GTW and tongue-weight spec, even if you're planning on towing only a small trailer. Don't forget to factor in the weight of the trailer's contents—including the capacity of the fresh-, gray- and black-water tanks—when you're shopping hitches.

Most hitches employ a removable drawbar, which holds the hitch ball. The bars come in two sizes: 1.25 inches (for lightweight pop-ups and bike racks) and 2 inches (for heavy loads).

Hitch balls come in three main flavors: 17/8 inches, 2 inches and 25/16 inches. Generally, the bigger the ball, the more weight it can support. If you own two or more trailers that call for different ball sizes, I recommend buying separate drawbars with the proper balls permanently attached.

Install the ball onto the drawbar to the proper torque—generally, several hundred foot-pounds. You'll have to use big tools and lots of muscle, and a generous squirt of threadlocker, which will keep moisture from penetrating the threads and freezing them up, allowing for easier removal.

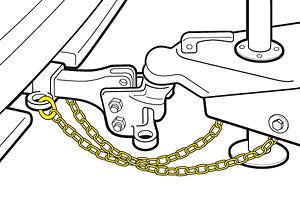

1. Cross the Chains for Safety

Chains serve as the hitch of last resort: If the tongue ever loses its grip on the ball, the chains will keep the trailer from vaulting the guardrail into oncoming traffic or something equally inconvenient. Cross the chains under the tongue—if it slips free, it'll land on top of the crossed chains rather than hitting the pavement. A bonus of the X configuration: The chains won't come up short in tight turns.

2. Check the Trailer-Wiring Harness

This industry-standard plug and socket wiring and color-coding scheme should make it easy to install the connector properly to the tow vehicle's harness. Spray the contacts with dielectric grease to prevent corrosion.

3. Always Check the Brake Battery

Trailers with electric brakes rely on a small gel-cell battery to initiate stopping when the breakaway lanyard is pulled. Normally, the battery charges whenever the truck engine is running. But it's smart to check it before hitting the road; faulty wiring or lengthy storage can sap the juice. Use a test light or voltmeter to make sure the battery is alive; if not, hook it up to an external charger to ensure the brakes are in working order.

4. Set Your Tongue Weight

Swaying trailers are almost always the result of insufficient tongue weight, because adding tongue weight adds stability.

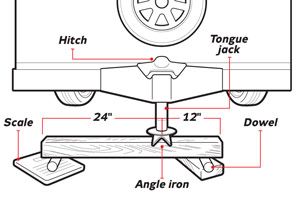

If there is zero tongue weight, the trailer's center of gravity (CG), the point around which it pitches, yaws and rolls, is centered between the tires' contact patches. This will provide no stability, specifically in yaw, or sway. Adding tongue weight, by moving cargo in the trailer forward, pulls the CG forward of the tire contact patches. The drag of the tires will tend to pull the CG back onto the centerline of the truck and trailer. The more tongue weight, the farther forward the CG goes, and the more stability in sway, right up until you add too much tongue weight for the tow vehicle's rear suspension to handle. Industry-wide, the target recommendation for tongue weight is 10 to 12 percent of total trailer weight. Here's how to check tongue weight if your trailer weighs so much that your bathroom scale won't read high enough. With the tongue resting on the beam one-third of the distance between the pivot and the scale, a 140-pound reading means that the total tongue weight is 420 pounds, just about right for a 4000-pound trailer.

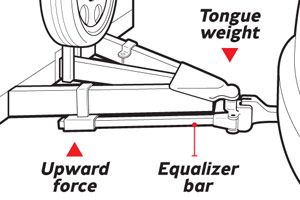

5. Set Up an Equalizing Hitch

Once you've dialed in enough tongue weight for stability (about 10 percent of the trailer's weight), there may be too much pressure on the vehicle's hitch. Equalizing bars (right) induce a rotational force around the hitch and pivot horizontally, transferring some of the tongue weight to the vehicle's front axle. The stiffness of the bars needs to be correct for your particular trailer, so consult the manual or a trailering specialist. I generally adjust them so that when the equalizer bars are installed, the trailer hitch rises back to within 1 inch of its unladen ride height.

Setting the Hitch Height

It's important that the loaded trailer be level to the ground when it's attached to the vehicle, and that you trim the trailer's flatness either with an adjustable drawbar or by finding one with the right offset. (If you end up using an offset drawbar, make sure it's rated to handle the trailer weight.)

First, you need to find the height of the trailer's tongue when the trailer is level. Set up the trailer on flat pavement. Run the tongue jack up and down or prop it up on some scrap lumber until it's level. You can determine this by placing a carpenter's level on the tongue or by eyeballing the trailer from the side from a distance of about 50 feet. Measure from the ground to the top of the ball socket. Park the vehicle you'll use to tow the trailer on level ground too. Then measure from the ground to the top of the hitch receiver and add 3 inches to accommodate the height of the ball.

Typically, the ball is a good bit higher than the trailer tongue, so the difference is the approximate amount the drawbar will have to be lowered. I say approximate because the weight of the trailer will compress the vehicle's springs. Hook up everything (with the trailer loaded) and again measure the trailer's attitude. You'll likely have to adjust the drawbar height again. I keep a few different drawbars on hand, but an adjustable one is a good investment.

Loading Up

Sure, you know how much the trailer weighs, because it's printed right there on the registration, right? Don't believe it, as the listed weight probably doesn't include a camper's furniture or the cargo on a utility trailer. Accessories added at the dealership, like an auxiliary battery, ramps, tie-down rails and whatnot, can make the gross weight climb substantially. (Don't complain to the trailer manufacturer—if your state charges by weight for the registration, you're saving a couple of bucks. ) The only real way to know is to weigh it, which you can do for a minimal fee at most stone-and-gravel yards, feed stores and truck stops.

Before you head to the scales, load up all the items that you plan to haul, and fill the water and propane tanks. After you arrive, first get the overall trailer weight by disconnecting the trailer and resting the entire rig, wheels and tongue jack on the scale. Next, find the tongue weight by hitching up the trailer and leaving only its tires on the scale. The difference between the two measurements is the tongue weight. You want roughly 10 percent of the trailer's weight on the tongue. Shift the cargo fore and aft until you get the correct weight distribution. Note the position of the load (a camera phone comes in handy for this) so you know for next time. And if you're changing cargo but don't have time to visit the scales, use our home-brew method (see "Set Your Tongue Weight") to get an accurate measurement.

Don't trust anything to stay put in or on a trailer once you're under way. Clip or bungee cabinet doors and drawers. Use ratchet tie downs to keep stuff in place.

Tires

Inflate the tires to the trailer manufacturer's maximum recommended cold pressure. Heat is the tires' enemy, and a properly inflated tire will run cooler. Be even more careful of the small tires on light-duty trailers—the tiny outside diameter means they spin faster. A high-speed run on a hot day with a ton of bricks on board could overheat the tires or wheel bearings.

Hooking Up

Whenever you hook up the trailer, check that all of the lights are working. You can do this without making four trips up to the cab and toggling on all the turn signals and brake lights in succession. Turn on the parking lamps and the hazard flashers. Walk to the back of the trailer. If the parking lamps and flashers are on, you've got turn signals and brake lights, because they're the same filaments as the hazards. This assumes, of course, that the truck's brake lights are working.

On the Road

Regardless of how tightly you cranked the tie downs on that car, bike or ATV, road vibration can loosen them. So, about 10 to 20 miles after you depart, stop and check their tension. After a few hours on the road—and every time you stop—inspect the trailer. Make sure the hitch and wiring are secure. Kick the tires to see if they're properly inflated. Tire pressure and properly functioning wheel bearings are crucial. Heat is the telltale sign: You just don't want any tire or wheel bearing to be significantly warmer than the others. I use an infrared thermometer—or my calibrated palm—to check the temperature of both. A tire becomes hotter if it has less air pressure than the others, so check for a leak. A toasty wheel bearing is on the verge of failing. At the very least, pop off the bearing cap to see if there's sufficient grease in the bearing cavity.

Every morning, check the tow vehicle and trailer tire pressure, as well as the trailer lights and brakes. Ditto for any tie downs. Don't forget to shut off the propane at the tank and the electric water pump at the breaker. If you've got an auxiliary battery, be sure it's turned off and connected to the vehicle charging circuit so it'll charge while you're under way.

One last tip: If you're trailering to a campground, leave the freshwater tank empty until you're on-site. No sense in towing several hundred pounds of water cross-country. Ditto for breaking camp: Empty the black-, gray- and fresh-water tanks at the campground instead of towing all that extra weight around.