POP Projects is a collection of new and classic projects from more than a century of Popular Mechanics. Master skills, get tool recommendations, and, most importantly, build something of your very own.

Summer's nearly here, and I'm ready for it. I've got a new seven-burner gas grill and four ground-shaking speakers for my outdoor sound system—and I've built a sturdy picnic table to replace my old one. (It was a creaky, splintered mess of lumber that listed to one side like a parallelogram.)

The new table took a weekend to construct, including a trip to a home center to hand-pick the lumber and buy fasteners. One of the project's best features: The top and bench seats are made from composite decking, a material fashioned from plastic resin and sawdust. It's easy to clean, it's impervious to wood-boring insects, and it never splinters. I chose pressure-treated 2x lumber for other parts of the project—and rust-proof fasteners everywhere. I have to admit that my design is heavy. On the other hand, it's durable; this is probably the last picnic table you'll ever need.

Some Tools You Might Need

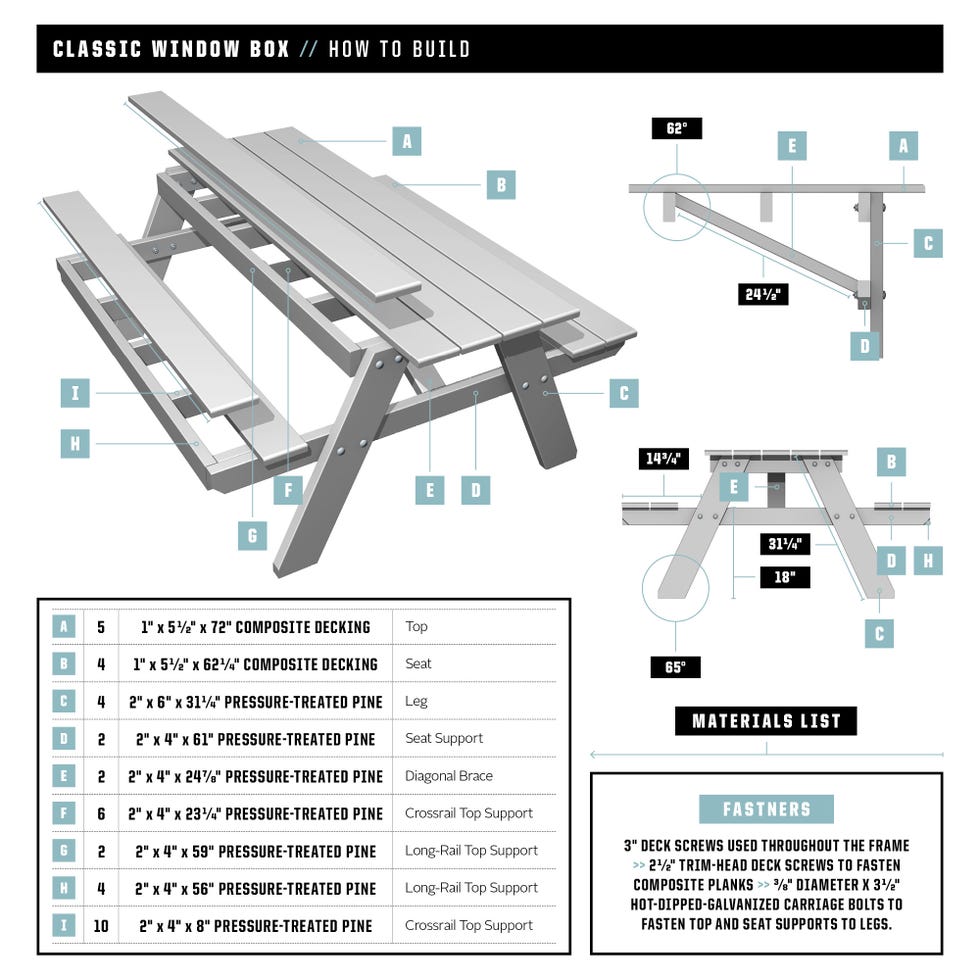

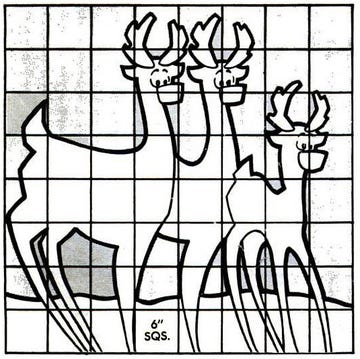

A Look At the Plans

Start From the Bottom

Begin by cutting four picnic table legs out of pressure-treated 2x6 lumber. Cut two legs at a time on a power miter saw [1]. You can also use a circular saw and a guide to cut the angles on the top and bottom of the legs.

Next, crosscut and bevel the seat support and lay the support across the legs. The tops of the supports should be 18 inches from the leg bottoms, and the ends of the supports should extend 143⁄4 inches from each leg. Secure the 2x4 supports to the legs with 3-inch deck screws [2]. Later, you’ll strengthen the joint with carriage bolts.

⚠️Be careful to drive the screw head flush but no deeper; otherwise, you risk the screw point poking out the other side.

Now move on to the frame for the tabletop. Crosscut the side rails, and pre-drill 5⁄32-inch pilot holes to prevent splitting; join the parts with 3-inch deck screws [3]. Duplicate the process to cut and fasten the seat frames.

Start the Assembly

The next step is to assemble the picnic table structure. First, position the tabletop assembly flush with the top of the legs and clamp it into place. At each end of the top, drive 3-inch deck screws through the inside of the frame and into the legs [4].

Later, install carriage bolts to bolster the joints. Fasten the seat frames by driving deck screws through the outside of the seat support into the frame [5].To reinforce the table base and ensure that it doesn’t tilt out of square, install two diagonal braces. Use a power miter saw or a circular saw to cut the angled ends on these pieces. Slip the braces between the seat support and top-frame cross support and secure them with 3-inch deck screws [6].

Finish It Up

Use a drill and a 13⁄32-inch-diameter bit to bore carriage-bolt holes through the legs and tabletop frame. To ensure that any splintering occurs on the inside face of the legs, run the bit from the outside to the inside. Use a hammer to tap the carriage bolts through the holes, slide on galvanized washers and nuts and tighten with a socket wrench [7].

⚠️If you use longer bolts than those I’ve specified, be sure to cut off any excess bolt shank and file the cut surface smooth. This will prevent the possibility of injury from a protruding shank.

Crosscut the composite decking for the top and seats. To increase accuracy, gang-cut several planks at once. Lay the decking planks across the frame with their woodgrain texture facing up. The planks should have a 5-inch over-hang on each end, and the end planks should project 1 inch. Bore 1/8-inch pilot holes through the plank and the frame [8]. Fasten the planks with 2 1⁄2-inch-long trim-head deck screws.

To maintain a uniform 1⁄4-inch gap between the planks, use plastic spacers designed for composite decking. Fit these between each plank. Finish the project by rounding off the square ends of each plank with a router and a 3/8-inch-radius rounding-over bit [9].

Finally, fire up the grill and sit down to your first meal at your new table.

Joe is a former carpenter and cabinetmaker who writes extensively about remodeling, woodworking, and tool techniques. He has written eight books and is a contributing editor to Popular Mechanics. He also appears on the Today’s Homeowner TV show, and co-hosts the weekly Today’s Homeowner Radio Show. Joe writes from his home in Roxbury, Connecticut.