Fall and spring are great times to overhaul your bike hubs—which all your fun rides have exposed to countless revolutions and all types of insidious contamination.

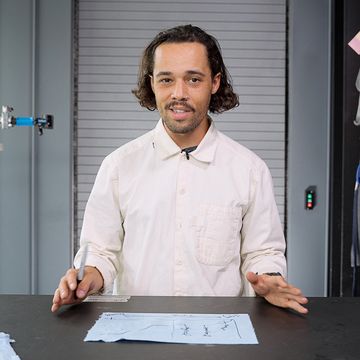

Here's how to maintain the most popular bike hub on the market, the Shimano sealed mechanism. (Sealed cartridge bearings are a different beast, so don't try this on them.) Like most hubs on the market, it uses an easily serviceable, but touchy-to-adjust cup-and-cone design. The "cups" are built into each side of the hub shell; the "cones" are conical-shaped nuts that screw onto the axle and apply tension to steel ball-bearings. If you don't have any experience working on your bike, teach yourself to do this and more with Bicycling's Quick & Easy Bike Maintenance course developed by Test Editor Mike Yozell.

- Remove the wheel from the bike. For the rear, remove the cassette with a freewheel tool.

- Remove the protective shoe that covers the nondrive-side assembly. Place a 15-mm cone wrench on the nondrive-side locknut, and a 13-mm (front) or 15-mm (rear) wrench on the driveside cone. Loosen the nondrive-side locknut and remove it from the axle.

- Remove the thin spacer under the locknut.

- Use a 15-mm cone wrench to remove the cone from the axle.

- Carefully pull the axle out of the hub shell. Catch the ball bearings that fall out of both sides with a small towel. Remove any stragglers with the screwdriver.

- Clean the ball bearings, axle and hub shell with a light biodegradable degreaser.

- Coat the cups with a layer of lithium-based lube 2-3 mm thick. Also apply grease to the assembled axle/cone/locknut unit.

- Replace an equal number of ball bearings in each cup. Little or no space should remain when the balls are back in place.

- Reinsert the axle (with drive side complete with cone, thin washer and lock nut) back through the hub.

- When the drive-side cone sits snug against the bearings, screw on the nondrive-side cone until it presses against the bearings.

- Hand thread the thin washer and locknut back onto the axle.

- Place a 17-mm wrench on the drive-side locknut and the 13-mm or 15-mm wrench on the loose cone. Turn the loose cone clockwise until it begins to tighten down on the bearings.

- Use a second 17-mm wrench to "lock down" this adjustment. Hold the locknut in place and back off the cone counter-clockwise. Because you back off the cone to lock it into place, you need to slightly overtighten it in step 12 to compensate--this is the "touchy to adjust" part. You have it right when you can easily roll the axle between your fingers without any resistance and there's no side-to-side slop.

- If the adjustment is too tight or too loose after you lock it down, loosen the locknut, tighten or loosen the cone and lock it down again.

- When it seems just right, back off the adjustment just a fraction of a turn to compensate for the compression load of the quick-release when the wheel is reinstalled. You're done.

TOOLS NEEDED

- Cassette/freewheel tool

- Adjustable Wrench

- Chain whip

- 13-mm cone wrench

- 15-mm cone wrench

- Two 17-mm cone wrenches

- Small flathead screwdriver

- Degreaser

- Lithium-based lube