Efficient and flexible light delivery has been dominated by solid-core silica glass optical fibers, especially in telecommunications and industrial lasers. But high-power laser light delivery, vital for industrial applications, faces significant challenges with traditional fibers due to nonlinear processes like the Kerr effect and stimulated Raman scattering in the core, along with the damage threshold of silica glass. These factors greatly limit the deliverable power densities.

In hollow-core fibers (HCFs), >99.99% of the guided light is contained within the central air (or vacuum) filled core, bypassing the limitations of solid-silica core or traditional fibers. In 2022, the Southampton team successfully demonstrated the advantages of a new HCF design, transmitting 1 kW of continuous-wave near-infrared light (~1 μm) through a 1-km length, showcasing the technology's potential.

In the latest work, the team has expanded these capabilities into the green wavelength, crucial for numerous industrial applications, by transmitting kilowatt-peak power 520-nm laser pulses through 300 m of HCF.

Developing HCFs for visible wavelengths presents fabrication challenges due to the small structural features.

The team also conducted a comprehensive nonlinearity study on practical air-filled, long-length HCFs. Nonlinearity in HCFs in the visible relative to the infrared region is significantly higher, which is attributed not only to the reduced fiber core size but also to the shorter operation wavelength. This advancement is a crucial step towards using green laser light in high-precision, efficient material processing, which will benefit sectors like e-mobility manufacturing, notably in battery production.

Hollow-core fiber for green laser power delivery

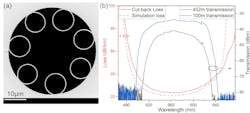

The HCF used in this work guides light via anti-resonance, in which a series of thin-glass membranes surround the fiber’s core and confine the guided light within it. This is achieved via a single ring of seven cladding capillaries (seven represents an excellent balance between loss, bend-loss, and modality).

The fiber is fabricated by the stack-and-draw method using Heraeus F300 fused silica glass, and has a ~20.7-μm core diameter, a mode-field diameter of ~14.5 μm, and guides light from 515 nm to 618 nm with <30 dB/km loss (see Fig. 1). The reported fiber is 300 m long, but the team in Southampton regularly produces multi-kilometer lengths via this process. The fiber is also relatively bend-loss insensitive, with <0.1 dB/m loss for bends with diameters >13 cm at the operation wavelength of 520 nm.

Power delivery results

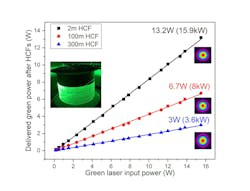

The power delivery experiments reported use an in-house-made 15.5-W, 520-nm, frequency-doubled ytterbium-doped fiber laser, producing 1.6 MHz repetition rate, ~520 ps pulses with ~18 kW peak power. The laser beam is focused to a 15-µm mode-field diameter to match the fibers, and results in a coupling efficiency of ~86%. HCF lengths of 2, 100, and 300 m were able to deliver average powers of 13.2, 6.7, and 3 W, corresponding to peak powers of 15.9, 8, and 3.6 kW, respectively (see Fig. 2).

The emergence of lower-loss and visible-guiding HCFs, now becoming available, is expected to enhance throughput efficiency and enable power delivery over kilometer-scale distances. Despite the energy density inside the fiber’s core reaching 5.5 J/cm2, no damage was observed in the fiber. The delivered beam quality, essential for precision micromachining and long-distance applications, was high across all the tested lengths (M2 <1.1).

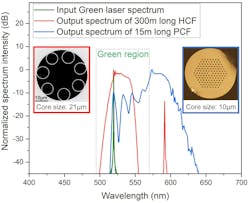

Overcoming nonlinear limits of solid-core silica fiber

The nonlinear limit of solid-core silica fiber is a particular challenge in the visible due to the decreased core size (necessary for single-mode operation) and causes significant spectral broadening. When compared to a 15-m long, 10-µm-core photonic-crystal fiber (PCF), with similar loss to the HCF used (and measured using the same setup), significantly more spectral broadening was observed than for the 300-m length of HCF (see Fig. 3), clearly demonstrating the advantage these HCFs possess in terms of nonlinearity.

This work again shows that HCFs are ideally placed to solve issues encountered with the flexible optical fiber delivery of laser light and offer the possibility for large-scale delivery of laser light (especially in the green/UV-visible) for industrial processes. This flexibility is seen as vital for various future manufacturing concepts.

Expert commentary

Richard Carter, associate professor at the Institute of Photonics and Quantum Sciences, Heriot-Watt University, and academic lead at the Precision Laser Application Labs of the National Robotarium, as well as vice president of the Association of Industrial Laser Users (AILU), notes:

"Flexible delivery of ultrashort laser pulses (USP) would break a significant barrier in the adoption of USP manufacturing processes in industry. These forms of anti-resonant hollow-core fiber have been seen as one of the most promising options for several years, but issues in drawing reliable lengths of fiber have made this slow to practically realize.

The results highlighted from Southampton University represent a significant leap forward. Not only are the fibers able to guide in the more challenging green region but crucially with lengths and performances that are clearly ready for commercialization and industrial implementation."

FURTHER READING

Q. Fu et al., Laser Photon. Rev., 2201027 (Jan. 2024); doi:10.1002/lpor.202201027.