Dear All Accelerated Wear Machine for Floor MUNRO ltd Tel: +44 (0) 20 8551 7000 Cavendish House, Parkway, Harlow Business Park, Harlow, Essex CM19 5QF UK, https://lnkd.in/dM2zZrmX

Munro Instruments Ltd, since 1864.

Industrial Machinery Manufacturing

Harlow, Essex 792 followers

EST.1864 Meteorological equipment, air sampling, floor slip testing, onsite slip testing, sample testing.

About us

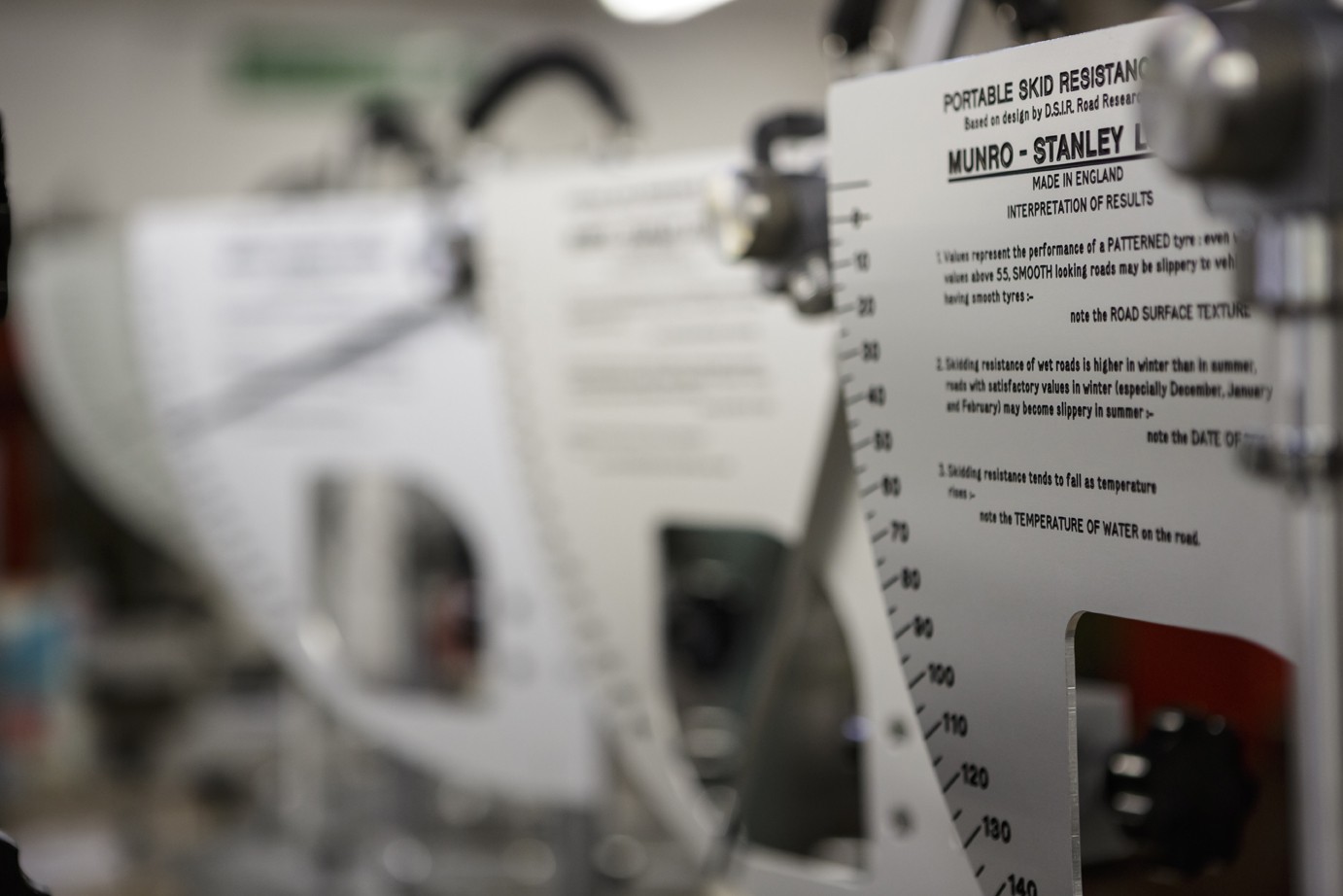

Munro Instruments specializes in the manufacture and supply of meteorological and environmental monitoring equipment. Over the course of our 150-year history, the company has achieved a global reputation for excellence in providing instruments and systems of the highest quality. Our core product lines focus on the supply of: Meteorological & Environmental Monitoring Equipment: Automatic Weather Stations and standalone sensors to enable the measurement of wind speed & direction, temperature, humidity, rainfall, barometric pressure, solar radiation, air quality, soil quality and water quality. We also manufacture Gravimetric Air Samplers for the assessment of workplaces and environments where airborne gases and dusts may be a hazard to health. Portable Skid Resistance Testers (also known as the British Pendulum Tester): This instrument is used worldwide for assessing the slip and skid potential of pedestrian surfaces and roads. We also have a team of engineers ready to visit you on site to provide a detailed health and safety report on your flooring. In-House testing on flooring samples also available. Our equipment is manufactured at our premises in Essex, United Kingdom, and is shipped to customers worldwide.

- Website

- http://www.munroinstruments.com

External link for Munro Instruments Ltd, since 1864.

- Industry

- Industrial Machinery Manufacturing

- Company size

- 2-10 employees

- Headquarters

- Harlow, Essex

- Type

- Privately Held

- Founded

- 1864

- Specialties

- Meteorology, Environmental Monitoring, Air Samplers, Slip Resistance, Skid Resistance, Occupational Health, fever monitoring, staff safety, laboratory equipment, temperature monitoring, health and safety, corona virus prevention, and covid19 prevention

Locations

- Primary

Get directions

44-45 Burnt Mill

Elizabeth Way

Harlow, Essex CM20 2HU, GB

Employees at Munro Instruments Ltd, since 1864.

Updates

-

Dear Madam/ Sir , I am excited to introduce our latest product, the Anaerobic Workstations, manufactured by Munro. The workstations offer a comprehensive range of features for processing, incubating, and examining samples without exposure to atmospheric oxygen. It provides a controlled environment with precise temperature and gas concentration controls, ensuring optimal conditions for anaerobic experiments. Our workstation is a reliable solution for your anaerobic work, whether you are conducting : microbiology research, clinical diagnostics, dental applications, research into the human gut microbiome, or industrial applications. Key features of our Anaerobic Workstation include: -Includes capacities for a large number of Petri dishes. -Multiple sizes of airlocks. -Sophisticated touchscreen interface for easy control.

-

Dear All Weather stations Full range of sensors and data loggers:wind speed,Temperature,Humidity, Barometric pressure,Solar radiation and more. Enclose catalog: https://lnkd.in/dkJ7DRzG

-

A wide variety of Meteorological Equipment #Anemometers #wind #meteorological

-

Really interesting visit yesterday, to complete Pendulum testing where the previous provider had conducted SlipAlert testing. It is no surprise that the man from the Pendulum manufacturer says, "Pendulum good", but let's take an objective view. Even if we assume that the SlipAlert does produce values equivalent to the Pendulum, it is basic science that when you are conducting a test you need effective controls if you are to measure your variables. In a friction test you are testing the friction caused when two materials move across each other. One material is the floor, the other is the rubber slider. If the slider is different for each test, then you can't know whether the different numbers reflect a difference in floor or slider. That's why we Pendulum operators spend so much time refacing expensive, controlled, verified sliders, to bring them back to an identical edge. Refacing the slider on a SlipAlert is difficult. I'm not aware of any controlled process for doing so, but there may be one. All of the SlipAlerts I have seen in action have had slider pads deeply scored and damaged, and that surface will inherently vary from test to test, depending on whichever surface it has previously been used on. This roughened slider produces the same anti-slip effect as a roughened floor. Operators using a damaged slider are essentially using an 'anti-slip slider'. Where the floor is rough and grip levels good, you are unlikely to see a significant difference. On smooth floors however, the floors where people slip, the floors that will need to be controlled if responsible parties are to prevent slips and reduce exposure to slip injury claims, the SlipAlert, and indeed any test using a very rough slider, will significantly exaggerate wet slip resistance readings. Looking at the table of results which compares mean wet 96/4S (shod) results between the two methods, this effect is brought into sharp focus. The smoothest surfaces (locations 3, 4 and 13) show huge differences between methods. In several locations (2, 6, 12 and 13) the SlipAlert test wrongly indicates a safe surface in wet conditions. This could very reasonably inform a relaxation of contamination controls. Slips would then be likely, and if an injury and subsequent claim arose responsible parties would find quickly from the (lawyer-directed) Pendulum test, that the floor in question was actually dangerously unsafe. At Location 13 the SlipAlert reported a *low* risk of slip in the wet. The test that would be conducted in the event of a fall/insurance claim/legal dispute indicated a *high* risk of slip. If you are using anything other than the HSE and UKSRG preferred Pendulum to fulfil your legal obligation to monitor slip risk and maintain safe floors, you are essentially rolling the dice with every pedestrian that crosses your floors. The Pendulum test *is* good. The saving on a quicker/cheaper/easier SlipAlert assessment will be absolutely dwarfed by the cost of a single slip.

-

Bit late I know, (I don't really follow the tennis truth be told!), but a little throwback photo from when they let me play at Wimbledon. I thought I'd perfected my swing but I was out after only 1 day. I've learned in my job you have to take the rough with the smooth. Pro tip: Don't drop the ball, stay out of court with a proper slip risk assessment. That's it, I'm out of puns now. Have a good day folks :-)