Abstract

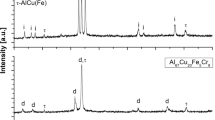

The recent invention of a new processing method for metals and alloys involving the addition of carbon has led to several reports demonstrating an enhancement in the mechanical properties of the materials known as “covetics.” In this work the corrosion behavior and mechanical properties of a 6061 aluminum–carbon covetic are investigated and explained. Covetic samples with carbon added were found to exhibit a corrosion potential 40–70 mV higher than samples processed without the addition of carbon. However, the corrosion current density of the covetic with carbon added relative to samples without carbon added was also increased. Surface characterization following the corrosion testing using scanning electron microscopy, energy-dispersive X-ray spectroscopy, and X-ray diffraction revealed significant differences between the covetic with carbon added and the covetic parent material processed without carbon addition. After corrosion, the surface of the covetic with carbon added showed a alloying element rich surface morphology from the parent alloy and exhibited a smaller grain size than the material processed without carbon. Additionally, changes in the mechanical properties of the covetic were observed with both the hardness and the compressive strength of the covetic increasing as a result of carbon addition. The observed change in corrosion behavior and mechanical properties of the covetic with carbon added, along with the physical characterization, are consistent with the formation of a secondary phase in the alloy induced by carbon addition during the process used to make the covetic.

Similar content being viewed by others

References

Smallman RE, Ngan AHW (2007) Physical metallurgy and advanced materials, 7th edn. Elsevier, Amsterdam

Natishan PM, O’Grady WE (2014) Chloride ion interactions with oxide-covered aluminum leading to pitting corrosion: a review. J Electrochem Soc 161:C421–C432

Burleigh TD (2003) Corrosion of aluminum and its alloys. In: Handbook of aluminum, pp 421–463

Hauffe K (2010) Chlorine and chlorinated water. In: Bender R (ed) Corrosion resistance of aluminum and its alloys. Wiley, Hoboken, pp 181–185

Rockel MB (2010) Sodium chloride. In: Bender R (ed) Corrosion resistance of aluminum and its alloys. Wiley, Hoboken, pp 367–465

Drodten P (2010) Seawater. In: Bender R (ed) Corrosion resistance of aluminum and its alloys. Wiley, Hoboken, pp 349–365

Twite RL, Bierwagen GP (1998) Review of alternatives to chromate for corrosion protection of aluminum aerospace alloys. Prog Org Coat 33:91–100

Liao J, Tan M-J (2011) Mixing of carbon nanotubes (CNTS) and aluminum powder for powder metallurgy use. Powder Technol 208:42–48

Bartolucci SF, Paras J, Rafiee MA, Rafiee J, Lee S, Kapoor D, Koratkar N (2011) Graphene–aluminum nanocomposites. Mater Sci Eng A 528:7933–7937

Bastwros M, Kim G-Y, Zhu C, Zhang K, Wang S, Tang X, Wang X (2014) Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Compos B Eng 60:111–118

Jeyasimman D, Sivaprasad K, Sivasankaran S, Narayanasamy R (2014) Fabrication and consolidation behavior of Al 6061 nanocomposite powders reinforced by multi-walled carbon nanotubes. Powder Technol 258:189–197

Zhao L, Lu H, Gao Z (2015) Microstructure and mechanical properties of Al/graphene composite produced by high-pressure torsion. Adv Eng Mater 17:976–981

Jeon C-H, Jeong Y-H, Seo J-J, Tien HN, Hong S-T, Yum Y-J, Hur S-H, Lee K-J (2014) Material properties of graphene/aluminum metal matrix composites fabricated by friction stir processing. Int J Precis Eng Manuf 15:1235–1239

Laha T, Agarwal A, McKechnie T, Seal S (2004) Synthesis and characterization of plasma spray formed carbon nanotube reinforced aluminum composite. Mater Sci Eng A 381:249–258

Laha T, Chen Y, Lahiri D, Agarwal A (2009) Tensile properties of carbon nanotube reinforced aluminum nanocomposite fabricated by plasma spray forming. Compos A Appl Sci Manuf 40:589–594

Qiu C, Metselaar R (1994) Solubility of carbon in liquid al and stability of Al4C3. J Alloys Compd 216:55–60

Shugart JV, Scherer RC, Penn RL (2012) Aluminum–carbon compositions, U.S. Patent US20120244033 A1

Salamanca-Riba LG, Isaacs RA, LeMieux MC, Wan J, Gaskell K, Jiang Y, Wuttig M, Mansour AN, Rashkeev SN, Kuklja MM, Zavalij PY, Santiago JR, Hu L (2015) Synthetic crystals of silver with carbon: 3D epitaxy of carbon nanostructures in the silver lattice. Adv Funct Mater 25:4768–4777

Bakir M, Jasiuk I (2017) Novel metal-carbon nanomaterials: a review on covetics. Adv Mater Lett 8:884–890

Forrest DR (2015) Approaches to high performance conductors, Next generation electric machines workshop, NIST, Gaithesburg

Forrest DR, Jasiuk I, Brown L, Joyce P, Mansour A, Salamanca-Riba L (2012) Novel metal-matrix composites with integrally-bound nanoscale carbon. In: Proceedings of Nanotech Conference and Expo, 2012, June 18–21, 2012. Santa Clara, CA, pp 560–563

Brown L, Joyce P, Forrest D, Wolk J (2011) Physical and mechanical characterization of a nano carbon infused aluminum-matrix composite. In: Proceedings of the SAMPE fall technical conference, Ft. Worth, TX

Nilufar S, Siddiqi S, Jasiuk I (2012) Multi-scale characterization of novel aluminum-carbon nanocomposites. In: Materials science and technology conference and exhibition 2012, MS&T, pp 701–707

Jasiuk I, Nilufar S, Salamanca-Riba L, Isaacs R, Siddiqi S (2013) Novel aluminum-carbon materials. In: Technical proceedings of the 2013 NSTI Nanotechnology Conference and Expo, NSTI-nanotech, pp 27–30

Salamanca-Riba L, Isaacs R, Mansour AN, Hall A, Forrest DR, LeMieux MC, Shugart J (2012) A new type of carbon nanostructure formed within a metal-matrix. In: Proceedings of Nanotech Conference and Expo 2012, pp 278–281

Jaim HMI, Isaacs RA, Rashkeev SN, Kuklja M, Cole DP, LeMieux MC, Jasiuk I, Nilufar S, Salamanca-Riba LG (2016) Sp2 carbon embedded in Al-6061 and Al-7075 alloys in the form of crystalline graphene nanoribbons. Carbon 107:56–66

Jaim HMI, Cole DP, Salamanca-Riba LG (2017) Characterization of carbon nanostructures in Al and Ag covetic alloys. Carbon 111:309–321

Knych T, Kwaśniewski P, Kiesiewicz G, Mamala A, Kawecki A, Smyrak B (2014) Characterization of nanocarbon copper composites manufactured in metallurgical synthesis process. Metall Mater Trans B 45:1196–1203

Knych T, Kiesiewicz G, Kwasniewski P, Mamala A, Smyrak B, Kawecki A (2014) Fabrication and cold drawing of copper covetic nanostructured carbon composites/otrzymywanie oraz ciągnienia kompozytów miedzianych typu covetic o strukturze nanometrycznej. In: Archives of metallurgy and materials, pp 1283–1286

Isaacs RA, Zhu H, Preston C, Mansour A, LeMieux M, Zavalij PY, Jaim HMI, Rabin O, Hu L, Salamanca-Riba LG (2015) Nanocarbon-copper thin film as transparent electrode. Appl Phys Lett 106:193108

Lim D-H, Negreira AS, Wilcox J (2011) DFT studies on the interaction of defective graphene-supported Fe and Al nanoparticles. J Phys Chem C 115:8961–8970

Reed JC, Zhu H, Zhu AY, Li C, Cubukcu E (2012) Graphene-enabled silver nanoantenna sensors. Nano Lett 12:4090–4094

Subramaniam C, Yamada T, Kobashi K, Sekiguchi A, Futaba DN, Yumura M, Hata K (2013) One hundred fold increase in current carrying capacity in a carbon nanotube–copper composite. Nat Commun 4:2202

Jablonski PD (2015) Melt processing of covetic materials, U.S. DOE advanced manufacturing office program review meeting, Washington, DC

Tian J, Cao H, Wu W, Yu Q, Guisinger NP, Chen YP (2012) Graphene induced surface reconstruction of Cu. Nano Lett 12:3893–3899

Isaacs RA, Jaim HMI, Cole DP, Gaskell K, Rabin O, Salamanca-Riba LG (2017) Synthesis and characterization of copper-nanocarbon films with enhanced stability. Carbon 122:336–343

Wang Y, Jiao MG, Song W, Wu ZJ (2017) Doped fullerene as a metal-free electrocatalyst for oxygen reduction reaction: a first-principles study. Carbon 114:393–401

Cogan SF, Gayle FW, Klein JD, Cocks FH, Shepard ML (1978) Extraction and X-ray analysis of phases in aluminium alloys. J Mater Sci 13:2687–2691. https://doi.org/10.1007/BF00552699

Li J, Dang J (2017) A summary of corrosion properties of Al-rich solid solution and secondary phase particles in Al alloys. Metals 7:84

Burleigh TD, Rennick RC, Bovard FS (1993) Technical note: corrosion potential for aluminum alloys measured by ASTM G 69. Corrosion 49:683–685

ASTM International (2012) Standard test method for measurement of corrosion potentials of aluminum alloys

Frankel GS (2016) Fundamentals of corrosion kinetics. In: Hughes AE, Mol JMC, Zheludkevich ML, Buchheit RG (eds) Active protective coatings: new-generation coatings for metals. Springer, Netherlands, pp 17–32

Stern M, Geary AL (1957) Electrochemical polarization: I. A theoretical analysis of the shape of polarization curves. J Electrochem Soc 104:56–63

ASTM International (2009) Standard test methods of compression testing of metallic materials at room temperature

Pourbaix M (1974) Atlas of electrochemical equilibria in aqueous solutions, 2nd edn. National Association of Corrosion Engineers, Houston

Sergiienko R, Shibata E, Akase Z, Suwa H, Nakamura T, Shindo D (2006) Carbon encapsulated iron carbide nanoparticles synthesized in ethanol by an electric plasma discharge in an ultrasonic cavitation field. Mater Chem Phys 98:34–38

Sivasankaran S, Sivaprasad K, Narayanasamy R, Satyanarayana PV (2011) X-ray peak broadening analysis of AA 6061100−x − x wt% Al2O3 nanocomposite prepared by mechanical alloying. Mater Charact 62:661–672

Kwon H, Leparoux M (2012) Hot extruded carbon nanotube reinforced aluminum matrix composite materials. Nanotechnology 23(41):415701

Mueller R, Kammler HK, Wegner K, Pratsinis SE (2003) OH surface density of SiO2 and TiO2 by thermogravimetric analysis. Langmuir 19:160–165

Cai J, Liu R (2007) Research on water evaporation in the process of biomass pyrolysis. Energy Fuels 21:3695–3697

Scari ADS, Pockszevnicki BC, Landre J, Magalhaes PAA (2014) Stress–strain compression of AA6082-T6 aluminum alloy at room temperature. J Struct 2014:7

Hansen N (2004) Hall–petch relation and boundary strengthening. Scr Mater 51:801–806

Hatch JE, Association A, Metals AS (1984) Aluminum: properties and physical metallurgy. American Society for Metals, Russell Township

Skoog DA, Holler FJ, Crouch SR (2007) Principles of instrumental analysis, 6th edn. Thomson, Belmont

Acknowledgements

J.A.V acknowledges a Robert Carr Fellowship from the Chemistry Department at the University of Illinois at Urbana-Champaign. J.A.V, A.M.D, X.C., and A.A.G thank the US National Science Foundation Grant CHE-1534184. M.B. and I.J. acknowledge DOE-STTR Grant (DE-SC0015115) and funding from the Air Conditioning and Refrigeration Center at the University of Illinois at Urbana-Champaign. This work was carried out in part in the Frederick Seitz Materials Research Laboratory Central Facilities, which are partially supported by the US Department of Energy (DE-FG02-07ER46453 and DE-FG02-07ER46471).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

10853_2018_2998_MOESM1_ESM.pdf

Supplementary material 1: Open circuit potential measurements and comparison to published literature, degradation rate curves for 2.3% covetic (PDF 340 kb)

Rights and permissions

About this article

Cite this article

Varnell, J.A., Bakir, M., DiAscro, A.M. et al. Understanding the influence of carbon addition on the corrosion behavior and mechanical properties of Al alloy “covetics”. J Mater Sci 54, 2668–2679 (2019). https://doi.org/10.1007/s10853-018-2998-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2998-5